Last night saw a little more progress on the chassis for the F8. I got it folded up and then soldered in the lace pins. They have done the trick nicely.

Monthly Archives: September 2013

Modelling in the Garden

The lovely weather this weekend has had me doing a bit of modelling in the garden encouraged by Chris to spend more time out side.

This is the fruits of my labours – the chassis with it’s cut outs for the horn blocks and the rivet holes drilled out for fitting brass lace pins because the etched rivets were too big…

And the ash pan and motion plate. The plan is to use this motion plate as a template to make a new one that fits with my slide bars.

Making steady progress

Despite having quite a busy social life at present with one thing and another I have still made some progress on the F8

I finished splitting the axles – they just need a final clean up – only one of these is for the F8 though (the one with the two splits)

And here’s the one that got away – I was doing them last thing at night and I can only surmise that I didn’t take enough time to work the epoxy fully through the spilt. The upside is that I can make use of the stub axles……. or so I am telling myself.

I assume that Slaters sell single axles?

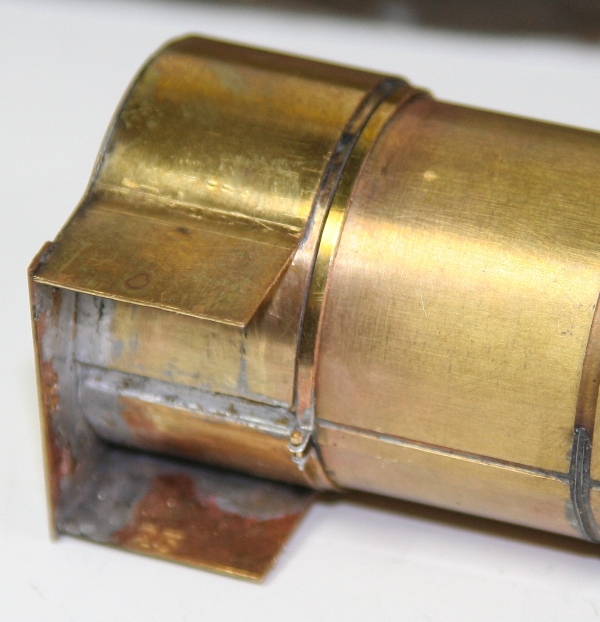

While the epoxy has been drying I also made small start on assembling the boiler.

As you can see from the photo the boiler bands are formed from a half etched recess and then an etched strip that fit’s in the recess but has folds/holes etched in for the cleats. I wondered if I could use a scale hardware stud to represent the fastener.

I have only done the one so far (and I need to centre it yet) – from the instructions there are two that will be visible beyond the ends of tanks. The rest need to be cut short when a cut out is made for the motor.

Regards Rob

A first attempt at split axles using GRP rod.

I am slowly but surely making progress.

I have now prepared the axles for epoxying. The observant among you will note that there are more axles than I need splitting for the F8 here. I had already drilled out the centres of 3 axles previously for one of my other tanks so I decided to drill a fourth the only one that I need for the F8 and then do the rest of the splitting on the four. Working on the mix plenty of epoxy up that every article on split axles that I have read recommends it seemed sensible to do a few while I have the job on the go.

In the main I followed Steph’s nicely documented method found here

The only deviations from Steph’s methods are that I used my pillar drill to drill out the axles and having tried a diamond slitting disk, as Steph recommends for cutting the GRP rod, I still got some fraying.

My alternative was to roll a scalpel blade backwards and forwards over it until it cut through (much like you would to cut microbore tube). It took a little longer but resulted in a nice clean cut with no fraying.

There are more holes than are visible in the photo above I just did a poor job of positioning them for the photo.

Next job is the messy one – epoxy here I come….