After doing battle with the cylinders and struggling with a drill bit broken off in one of the valve guides which I have yet to resolve (but I do have a fall back position should I need it) I decided that for a bit of light relief I would make up the bogie and trailing truck.

I started with the trailing truck for now other reason than I had some of the bit’s already removed from the fret during the course of removing other bits.

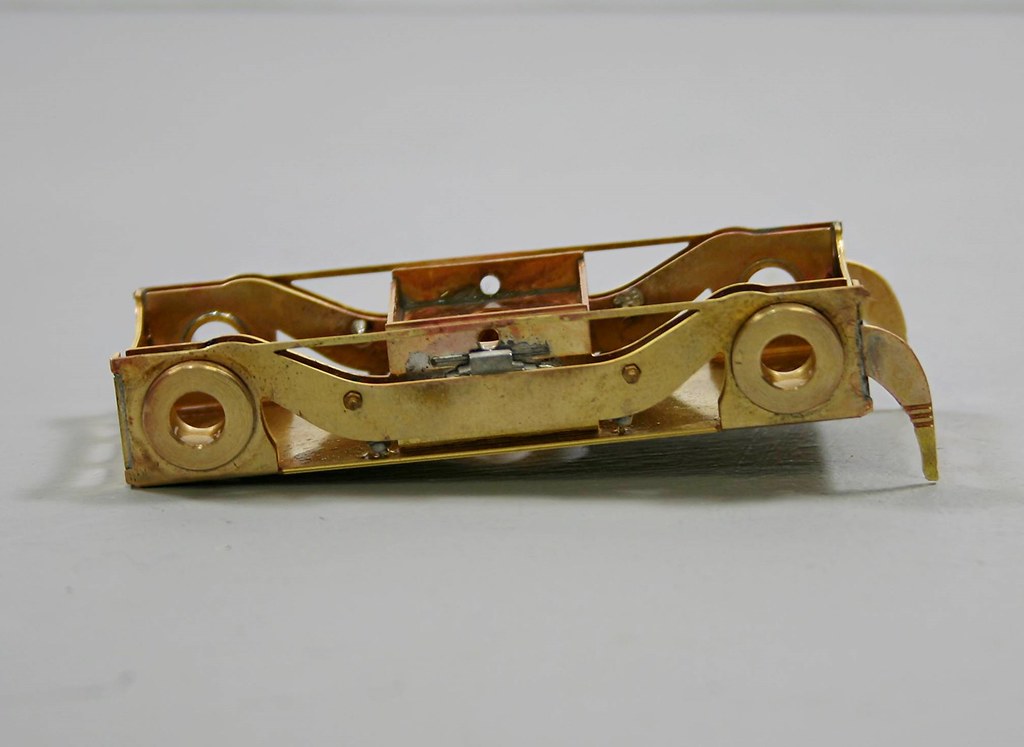

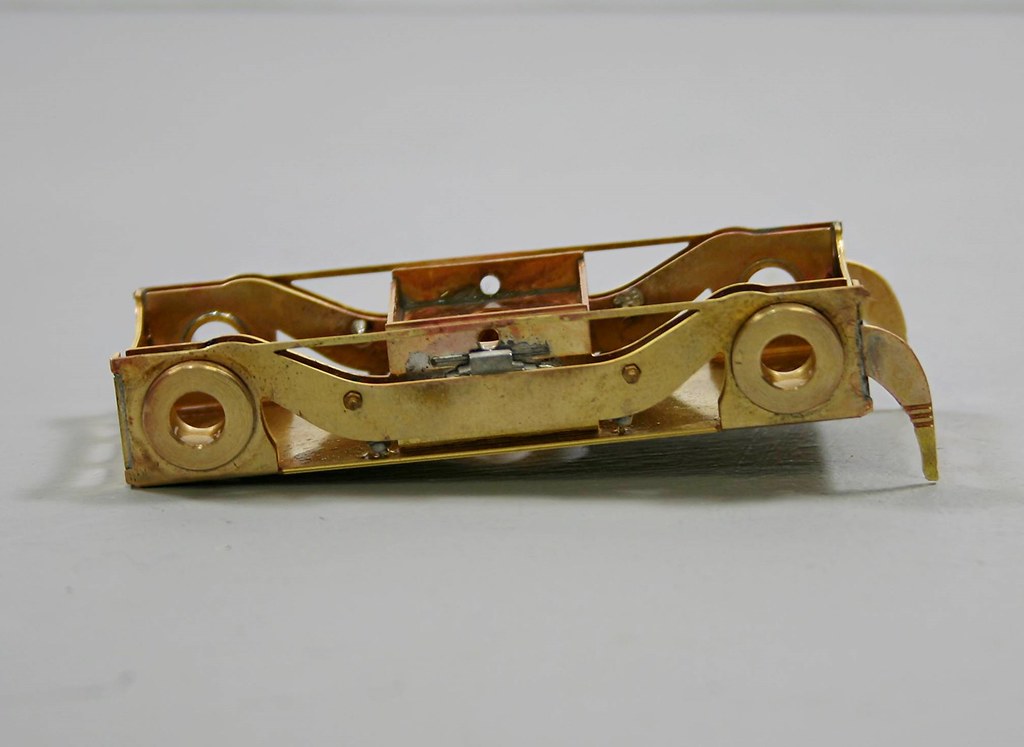

DJH Streamlined Coronation – Trailing Truck

DJH Streamlined Coronation – Trailing Truck

DJH Streamlined Coronation – Trailing Truck

DJH Streamlined Coronation – Trailing Truck

Sadly I had got to this bit when I realised that I had made an error in my interpretation of the instructions. You get two options of spring/axle box for the trailing truck. You get an axle box and full thickness spring combined and an etched spring separate axle box and some hanger castings. There are also a pair of thinner springs which I had attached as in the photos above.

The idea being that you use the full thickness castings for loco where they are to be used on track radius of greater than 7 feet or use the etched ones for less than 7 feet radius. It was only when looking at the bogie that I realised the the thinner cast springs were in fact for the bogie rather than the trailing truck and it all made sense. thankfully it was the work of a few minutes to swap them over and put the etched ones where they belong. There were some castings provided for the spring hangers as I mentioned but 2 of them were missing so I cut some off the thicker castings to make up the set.

DJH Streamlined Coronation – Trailing Truck

Tonights task is to solder the pins into the back of the hole as I would have done with a rivet of Premier Rods. Onwards and Upwards…..

Tonights task is to solder the pins into the back of the hole as I would have done with a rivet of Premier Rods. Onwards and Upwards….. ) the whitemetal bits.

) the whitemetal bits.